A few weeks ago, I went down to Osaka to see Adler’s exhibition the set up in collaboration with some students at the Osaka Designers’ College. In this collab, Adler asked students to come up with different aspects of Adler and make a presentation displaying their ideas. From this, Adler would choose from five different ideas and decide which of the five projects to choose from. Adler ultimately went with a project that focused on the manufacturing of Adler boots and created a space from there.

In order to come up with these presentations, the students had to study Adler, with several making visits to Adler’s factory to see how the boots were made. For Adler’s part, they decided to use lots of different samples to display the kind of boots they could make. Some examples of these are a crocodile upper boot, which had to be carefully stitched because with crocodile leather the scales determine where the stitching is. While the result looked and felt nice, I was told that it was also very time consuming. Another sample that Adler had on display were some boots made of Italian leather, which felt fantastic in hand, and I would argue would be a good boot to bring to production.

I also had the chance to interview some of the students involved, specifically Miss Yokota and Miss Kitai. The whole process started last April and until the summer to come up with the presentation. From there their presentation was selected. However, due to constraints the exhibit would be put up in February of this year.

Because of similar constraints, the students only had two weeks to create and put together the space. Given these limitations, what the students made was impressive and looked professionally done. One of the students had studied shop design and used that to come up with the collages of photos. She also took the photographs and the video of the boots being made.

At the entrance of the room the students put a small notice explaining their design decisions and direction. This particular idea of a factory tour was used because it helps show off things that cannot be seen when purchasing the boots, such as the detailed work process and the expert craftsmanship need to create the boots. The students also decided to come up with this idea to help represent Adler’s value as a brand. That being, one that is dedicated to craftsmanship and details and is defined by the level attention that is given to each boot when it is created.

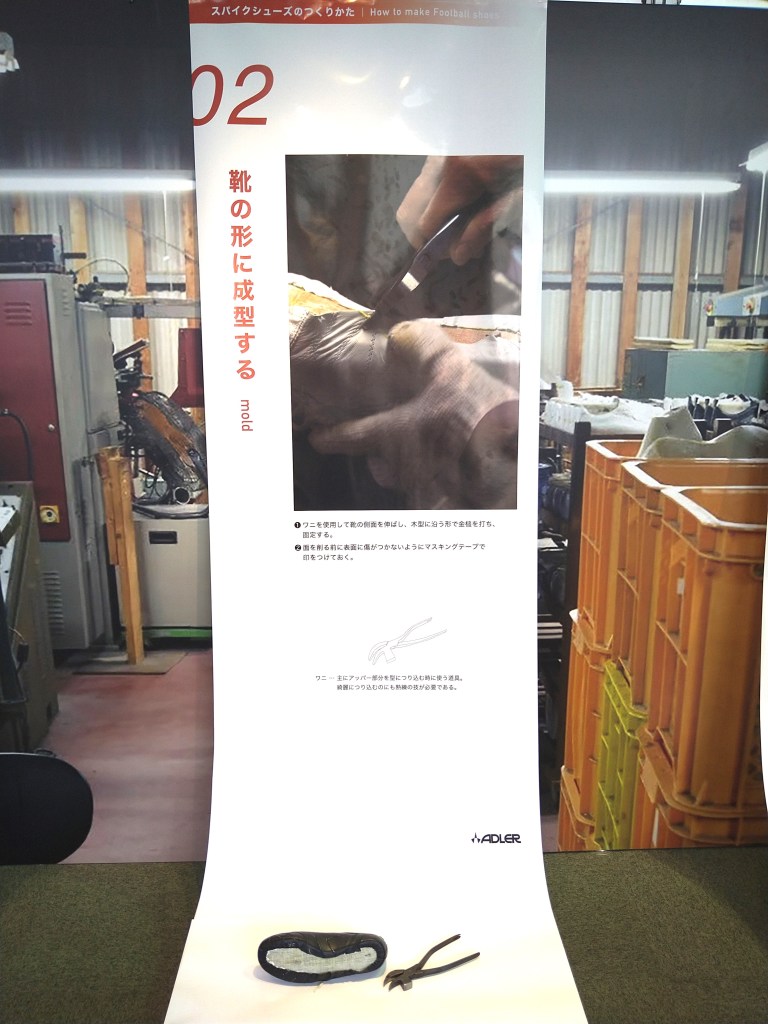

The overall display space was in a smallish room, but the use of space was cleverly used. The students had determined that the boots were made in a five step process.

First, the leather is put on the last and they shape the heel cup and the heel of the boot. This is followed by steaming the toe box to make it stretch easier.

Secondly, they wrap and stretch the leather around the foot mold using a tool and then hammering into place around the mold. Next, they put masking tape around the bottom of the boot.

Third is to make small wrinkles along the soleplate so that the glue will not fall off when applied.

Fourth, they apply glue to the bottom of the shoe and let it dry for twenty minutes. What the glue is made of varies from company to company and is normally a closely guarded secret. After about twenty minutes the glue is activated by being reheated and then the soleplate is attached to the upper.

Finally, the soleplate is stitched to the upper. Adler points out that this not only improves the durability of the boots but also helps with performance.

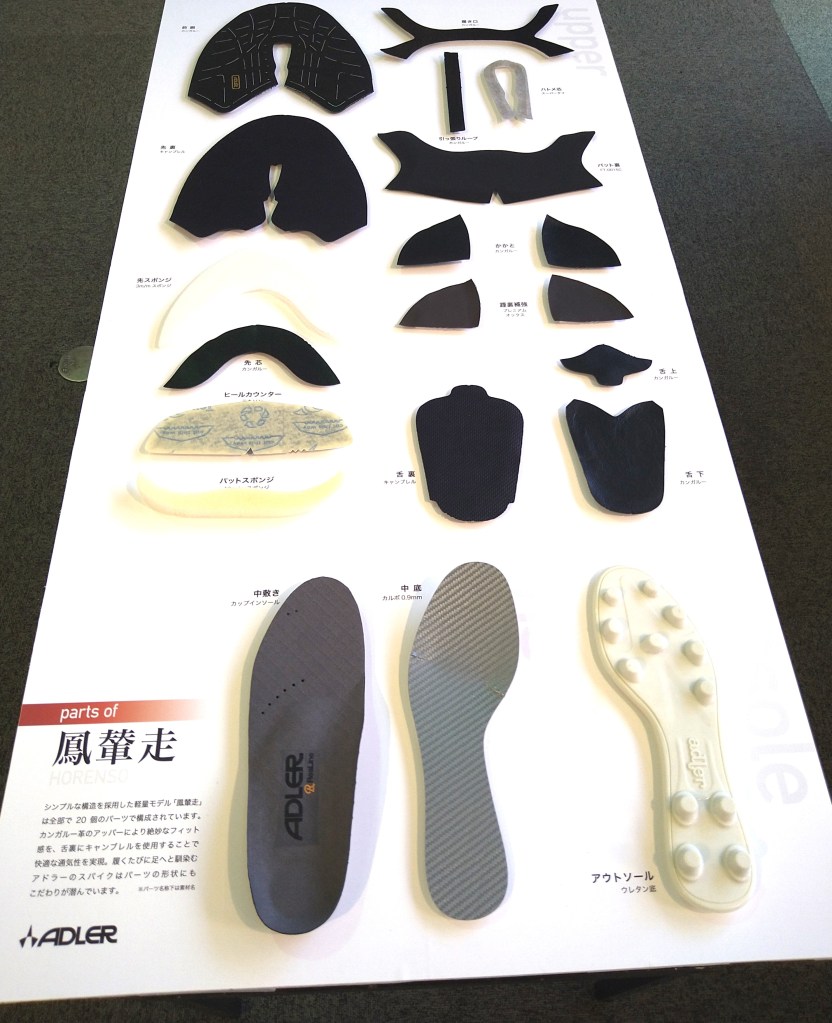

Going back to the space itself, there was a TV in corner with a video showing the process being made, which I thought was a nice touch. In the center of the room was a complete breakdown of the Horenso which in future would make for a great display piece in a store. Adjacent to that were the previously mentioned samples which also included a sample from every boot in Adler’s current line up.

Around the outside of the exhibit there was a collage of photos showing various aspects of Adler’s boots, with even more samples displaying what Adler could do, such as custom colours and the like.

A personal highlight for me was getting to once again talk to Mr. Nakamura, the master craftsman of Adler. He was quite impressed with the exhibit and seemed proud that his work was put on such a display.

Overall, I would say the exhibition was successful since it was well put together and had some interesting visitors attend. The local media was even involved and for such a small company Adler seems well poised to have some massive success in the future.

I want to personally thank Mr. Ryoichi Nakamura (Head Craftsman of ADLER), Mr. Takuya Murayama (co-CEO of ADLER), Mr. Keiji Suzuki (co-CEO of ADLER), The Osaka Designers’ College, Mr. Masaki Nagao (Director/General Manager of ODC), Mr. Satoshi Ninoyama (Project Leader/Advisor of ODC/Nono Inc.), Mr. Tsutomu Matsumoto, Hiroki Mikami, Tomonobu Uchikoshi (ODC Teachers) as well as the students involved and everyone at ADLER. Congratulations to the Group C Team (Matsumoto, Umeda, Nakamura and Kitai).

Please share this with your friends and make sure to follow me on Instagram and Facebook!

じゃあね!